Guide to Pond Liners in Australia: Selecting the Right Material for Your Water Feature

By Hydro Experts | 5 May 2025

In the residential garden and commercial site. Whether you are designing a wildlife pond, an ornamental water feature, or a water holding reservoir for irrigation, choosing the right liner is crucial in achieving the success of your water feature. In this guide, we will look at three popularly used liner types in Australia: PVC, HDPE, and EPDM - their characteristics, benefits, and the best uses for our Australian conditions.

Understanding the Importance of Quality Pond Liners

Before going into detail about particular materials, it is helpful to understand why liner choice is important. Australia has a varied climate, from tropical in the north to cooler temperate climates in the south, which presents challenges for water features. The intensity of UV radiation, temperature variations, and soil conditions all affect the performance and longevity of liners.

A quality pond liner serves several critical functions:

- Creates a watertight barrier between the soil and your pond water

- Protects groundwater from potential contamination

- Maintains water quality and clarity

- Provides structural stability to your water feature

- Withstands environmental stresses specific to your region

Now, let's examine each liner type in detail.

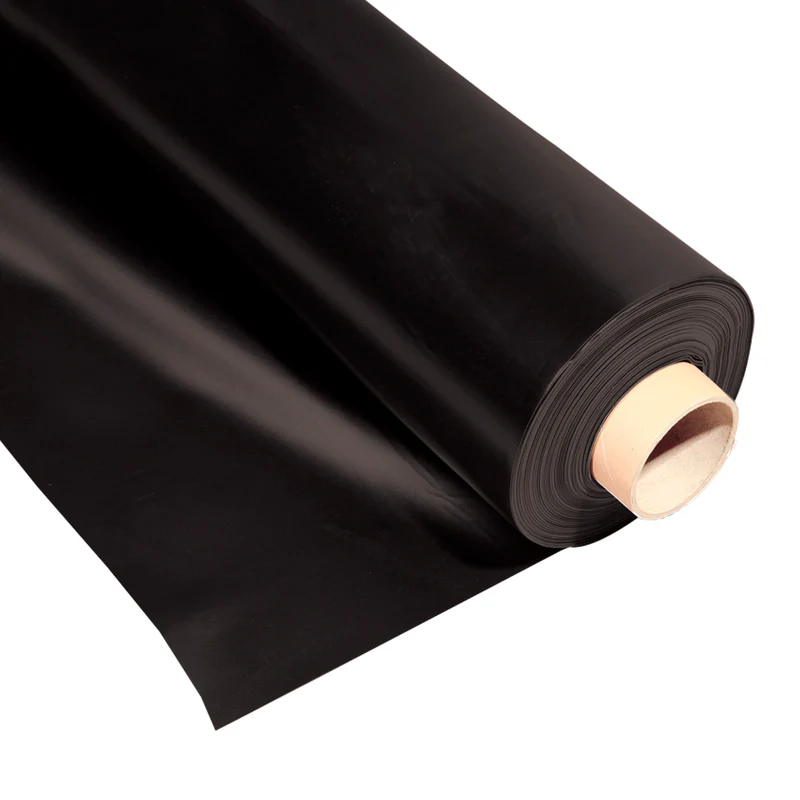

PVC Liners: Versatility and Value

Polyvinyl chloride (PVC) liners remain one of the most commonly used options for Australian ponds, primarily due to their affordability and accessibility.

Characteristics of PVC Liners

PVC liners are usually between 0.25mm and 1mm thick, made using a flexible form of PVC that has plasticisers for flexibility. PVC liners are made in a range of colours, although black is the most common, as it limits the growth of algae and blends well with the constructed watercourse.

Advantages in the Australian Context

For Australian pond owners, PVC offers several distinct benefits:

Cost-effective: PVC is typically the cheapest of the three types of liners (and, given pricing differences in markets, if you run the numbers, the PVC can also be the cheapest option for big projects where liner costs are only one part of the total project).

Flexibility and handling: The material is relatively light and offers good workability, meaning that installation is not overly difficult for an inexperienced DIYer. The inherent flexibility allows it to conform to the irregular shapes and contoured areas of a garden pond that is intended to look natural.

Availability: PVC liners are easily available all over Australia, from specialist pond supply suppliers to hardware chains in both metropolitan and rural centres.

Limitations to Consider

While PVC presents an attractive option, there are important considerations specific to Australian conditions:

Exposure to UV radiation: Australia's extreme sunlight can quicken the degradation of PVC Liners, which can result in a loss of useful life for the liners. This is much more of a concern in the northern parts of Australia, where UV radiation exposure is much greater.

Temperature performance: PVC becomes less flexible in cold temperatures (much less of a problem in most of Australia's temperate zones) and has the potential, when exposed to high temperatures, to expand in size and cause stress points or wrinkles.

Environmental considerations: Some PVC products may contain phthalates or other chemicals that have raised environmental concerns. If ecological impact is important to you, look for eco-friendly PVC formulations that are becoming increasingly available in the Australian market.

Ideal Applications

PVC liners work particularly well for:

- Smaller to medium garden ponds

- Temporary water features

- Projects with budget constraints

- Ponds in areas with moderate UV exposure

- Water features with simple designs

HDPE Liners: Durability for Demanding Applications

High-Density Polyethylene (HDPE) liners are one step above in terms of durability, which is why they are becoming more frequently used for the more demanding water containment applications throughout Australia.

Characteristics of HDPE Liners

According to the Mined Land Planning Initiative Painting Australia Cleaning, it is important for people with water surface infrastructure to be aware of the following characteristics of HDPE Liners.

HDPE Liners are made from a thermoplastic polymer characterized by its high strength-to-density ratio. HDPE recently became available in thicknesses often seen above 0.75mm to 2mm or more for commercial applications. It is highly resistant to chemical attack and maintains its integrity over a wide range of temperatures.

Advantages for Australian Applications

Superior UV resistance: For the Australian market, one of the most appealing factors of HDPE is its superior resistance to UV degradation. This quality makes HDPE particularly valuable in exposed applications where it may be subjected to the Australian sun.

Puncture resistance: HDPE also provides significantly greater puncture resistance and tear resistance to PVC, reducing the likelihood of damage during installation or due to root penetration damaging the membrane—something to be mindful of in the Australian landscape due to the prevalence of native flora.

Chemical stability: The main advantage of HDPE is its resistance to breakdown from most chemicals, making it the best option in situations where water quality may vary, or when treatments are applied regularly in applications like koi ponds or other commercial water features.

Longevity: With proper installation, HDPE liners can last 20+ years even in challenging Australian conditions, offering better long-term value despite higher initial costs.

Limitations to Consider

Rigidity: HDPE offers less flexibility compared to PVC or EPDM, which makes it more difficult to install, especially with complex designs involving tight corners or vertical applications.

Joining requirements: Regarding seams, an HDPE seam—watertight —typically needs a welding machine and skilled technicians. Depending on the application, you may have to hire a professional installer to get the seams correc,t depending on your preferences.

Cost factor: HDPE is more cost-effective than EPDM, but HDPE has a higher upfront cost than PVC liners, which could have some impact on project planning and budgets.

Ideal Applications

HDPE liners excel in:

- Larger water features and ponds

- Agricultural and irrigation reservoirs

- Commercial applications

- Regions with intense UV exposure (e.g., Queensland and Northern Territory)

- Situations requiring chemical resistance

- Projects where longevity justifies higher initial investment

EPDM Liners: Premium Performance

Ethylene Propylene Diene Monomer (EPDM) Liner is the best choice of pond liner on the market in Australia, with the best properties, but the most expensive.

Characteristics of EPDM Liners

EPDM is a synthetic rubber membrane that has great flexibility and outstanding durability. These liners are usually available in thicknesses ranging from 0.75mm - 1.5mm, with specially-formulated membranes available for water applications, ensuring safety for fish and plants.

Advantages in Australian Conditions

Exceptional elasticity: EPDM is capable of expanding to over 300% of its original size without losing integrity. This means it is an excellent choice for accommodating ground movement, which is an important feature for Australia's regions prone to ground movement in conjunction with dry and wet cycles.

Superior lifespan: EPDM liners are able to last 30+ years when correctly installed and maintained, even in the difficult Australian conditions, thus offering great value in the long term, despite the greater initial cost.

Temperature stability: The flexible nature and performance of EPDM is retained in very low - high temperatures (-40°C to 120°C), meaning it is suitable for all Australian climate zones from alpine regions to tropical north.

UV and ozone resistance: EPDM possesses great resistance to degradation due to sunlight and atmospheric ozone, which is crucial in often berating environmental conditions in Australia.

Fish and plant safety: Aquatic-grade EPDM is non-toxic to pond life, and to ecosystem ponds supporting native Australian environmental conditions in ponds with aquatic species

Limitations to Consider

Premium pricing: EPDM represents the most expensive option among common pond liners, which can significantly impact project budgets, especially for larger installations.

Weight factor: The material is heavier than PVC or HDPE, potentially making handling more challenging during installation.

Limited local manufacturing: Most EPDM pond liners are imported, which can affect availability and lead times in some parts of Australia.

Ideal Applications

- EPDM liners are particularly well-suited for:

- Premium water features

- Koi ponds and aquatic ecosystems

- Irregularly shaped designs benefiting from material elasticity

- Areas with significant ground movement

- Projects where maximum lifespan is a priority

- Installations where stretching around rocks or complex features is required

Making the Right Choice for Your Australian Project

Selecting the optimal pond liner requires balancing several factors specific to your situation:

Climate Considerations

Australia's diverse climate zones demand different performance characteristics:

Northern tropical regions: In Queensland and the Northern Territory, when UV endurance and heat stability are essential, HDPE and EPDM are better than PVC.

Southern temperate zones: In Victoria and Tasmania (and even NSW), considerations of temperature flexibility become more important as seasons have more severe variability. EPDM's performance in extreme temperatures presents benefits.

Arid central regions: Material durability is critical in climates with substantial temperature variability and extreme UV exposure; considering material durability, EPDM typically outlasts HDPE or PVC to some extent, material costs notwithstanding.

Project Specifics

Size and scale: Material cost escalates rapidly for large projects. PVC may only be a financially viable option for very large water features. Small premium ponds may make a higher price point for EPDM acceptable.

Design complexity: When dealing with complex shapes that include tight contours and vertical surfaces, EPDM is a great option because it has extraordinary elasticity. Simpler installations may only be able to make use of more rigid materials.

Intended lifespan: Think about the permanence of your water feature. Temporary or medium-term installations may not warrant the high price of premium materials. Permanent or legacy projects, which may last a generation, are worth the investment in maximum durability and long-term ROI.

Installation Considerations

DIY vs professional: Both PVC and EPDM can be done by a competent DIY enthusiast, however HDPE may require specialized welding machines and abilities.

Underlayment requirements: There are also all types of liner materials that benefit from quality underlayment materials to protect against punctures from below, particularly with the rocky soils and root systems we have in Australia.

Seaming needs: Larger jobs that require multiple sheets should consider the best way to seam the sheets together. EPDM has specialized tape systems, PVC can be solvent-welded, and HDPE requires heat welding.

Beyond the Basics: Additional Considerations

Environmental Impact

Increasingly, Australian consumers are considering the ecological footprint of their building materials:

PVC concerns: Traditional PVC has raised environmental questions due to its manufacturing process and additives, though eco-friendly formulations are increasingly available.

HDPE sustainability: While petroleum-based, HDPE is readily recyclable and free from many concerning additives.

EPDM lifecycle: Though EPDM represents a significant resource investment in manufacturing, its exceptional lifespan means fewer replacements and less waste over time.

Warranty Considerations

Australian consumer law provides certain guarantees, but manufacturer warranties vary significantly:

PVC warranties: Typically range from 5-15 years, depending on thickness and quality.

HDPE guarantees: Often come with 15-20 year warranties when professionally installed.

EPDM coverage: Premium products frequently offer 20-30 year warranties, reflecting their superior durability.

Always verify warranty terms and conditions specific to Australian installations, as international warranties may not fully apply to our unique conditions.

Conclusion: Investing in Quality for Australian Conditions

No matter what material you select, the quality of the pond liners is very important. Australia's weather conditions require materials that are able to withstand destructive UV radiation, temperature extremes, and occasional drought and flooding cycles.

PVC is a good option with affordability and versatility for many applications, however, HDPE is great for larger or more severe installations as it is very durable. Finally, for performance and longevity, EPDM is top of the line, although it does come at the highest price point.

By thoroughly assessing your intended use, local climate, and long-term goals, you can choose a durable pond liner that will, hopefully, provide decades of service, with opportunities for vibrant aquatic habitats to prosper, and fantastic additions that will add to your Australian landscape for generations.

Also, keep in mind that proper installation methods and correct underlayment kinds are just as important as the liner. You have the correct liner to start your journey, whether to create a wildlife habitat, a peaceful water garden, or a statement water feature, your aquatic vision can only thrive with the correct liner.

HDPE and EPDM liners offer the best UV resistance for Australian conditions.

PVC is affordable but less durable; it's better for small, budget-friendly, or temporary ponds.

Yes, PVC and EPDM can be DIY-installed; HDPE usually needs professional welding.

PVC lasts 5–15 years, HDPE around 20 years, and EPDM can last 30+ years with proper care.

Yes, using an underlay protects the liner from sharp rocks, roots, and soil movement.