How to Choose the Right Water Chiller Size for Your System?

By Hydro Experts | 30 October 2025

Water Chiller Sizing Guide

Choosing the wrong water chiller size creates problems. An undersized chiller runs constantly. It fails to cool your water properly. An oversized chiller cycles on and off too frequently. This wastes energy and wears out the unit. Selecting the correct size is essential for efficiency and stable temperatures.

This guide shows you how to choose the right water chiller size. We provide the steps to calculate your system's specific needs. You will learn how to account for your water volume, heat load, and target temperature. These instructions apply to hydroponics, aquariums, and cold plunge baths. Follow these steps to make an informed decision.

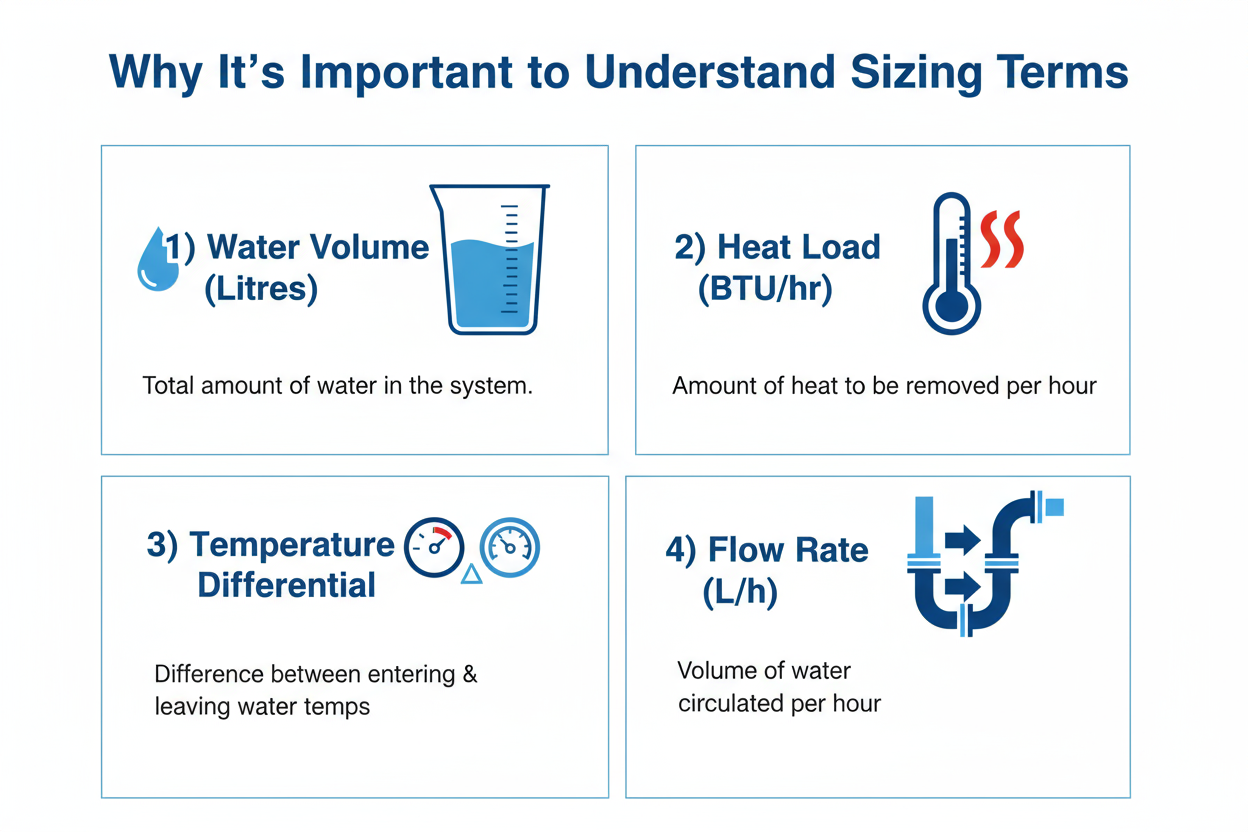

Why It's Important To Understand Sizing Terms?

You must understand a few key terms before you calculate your needs. These factors determine the correct chiller size for your application.

Water Volume (Litres)

Your system's total water volume is the starting point. This includes all the water in the reservoir, tank, sump, and plumbing. A larger volume of water requires more energy to cool. You must measure this volume accurately. An incorrect volume leads to a wrong chiller choice. Calculate it by measuring the dimensions of your container. For square or rectangular tanks, the formula is simple: Length x Width x Height.

Heat Load (BTU/hr)

Heat load is the total amount of heat entering your water system. The chiller's job is to remove this heat. Heat load is measured in British Thermal Units per hour (BTU/hr). One BTU is the energy needed to raise one pound of water by one degree Fahrenheit. Major sources of heat include equipment and the surrounding environment.

Equipment like water pumps, air pumps, and lights generates significant heat. Submersible pumps transfer almost all their heat directly into the water. External lights over a hydroponic system or aquarium also radiate heat downwards. The wattage of your equipment helps you estimate this heat load.

Temperature Differential (ΔT)

Temperature differential is the difference between your starting water temperature and your desired target temperature. It is often written as ΔT, or delta T. For example, your ambient water temperature might be 26°C. Your target temperature for hydroponic nutrient solution is 20°C. The temperature differential is 6°C.

A larger ΔT requires a more substantial chiller. You need more cooling power to achieve a bigger temperature drop. You must define a realistic target temperature for your specific application to calculate this value correctly.

Flow Rate (L/h)

Flow rate measures the volume of water that moves through the chiller in one hour. It is measured in litres per hour (L/h). Every chiller has an optimal flow rate range specified by the manufacturer. If your pump's flow rate is too low, the water stays in the chiller too long and might freeze.

If the flow rate is too high, the water moves through too quickly. The chiller does not have enough time to cool it effectively. Matching your pump's flow rate to the chiller's requirement is critical for performance.

Step-by-Step Guide to Calculate Chiller Size

Follow these three steps to determine the correct chiller size for your system. These calculations remove guesswork. They ensure you select a unit that meets your demands without wasting electricity.

Step 1: Calculate Your Total Water Volume

First, find the total volume of water in your system. Use a tape measure to get the dimensions of your tank, reservoir, or tub in centimetres.

The formula for a rectangular container is:

For a cylindrical container, the formula is:

Note: π (Pi) is approximately 3.14. The radius is half the diameter.

Always measure the actual water level, not the total height of the container. If you have an external sump or other connected containers, calculate their volumes separately and add them together.

Example for a hydroponic reservoir:

A reservoir is 120 cm long, 60 cm wide, and filled to a height of 30 cm.

Volume = 216,000 / 1000

Total Water Volume = 216 Litres

Step 2: Determine Your System's Heat Load

Next, calculate the total heat being added to your water. This comes primarily from equipment.

The conversion factor is:

List all the equipment that adds heat to your system. This includes water pumps, air pumps, filters, and lights. Find the wattage of each device. The wattage is usually listed on the product label.

Formula for equipment heat load:

Example for a hydroponic system:

- Submersible water pump: 50 Watts

- Air pump: 25 Watts

- Grow light radiating heat onto the water surface: 600 Watts

Total Heat Load = 675 W x 3.41 BTU/hr

Total Heat Load = 2301.75 BTU/hr

This number represents the heat the chiller must constantly remove to maintain a stable temperature.

Ambient temperature also adds heat. A system in a hot garage needs more cooling power than one in a climate-controlled room. It is difficult to calculate this environmental heat load precisely. A common practice is to add a safety buffer to your equipment heat load calculation. For a warm environment, add a 25% buffer. For a climate-controlled space, a 15% buffer is often enough.

Example with a safety buffer:

The system is in a warm grow tent.

Adjusted Heat Load = 2877 BTU/hr

You need a chiller that provides at least 2877 BTU/hr of cooling to keep your water temperature stable.

Step 3: Combine Factors for Your Final Choice

The final step involves choosing a chiller that meets your calculated heat load requirement. Most chiller models are rated by BTU/hr or Horsepower (HP). Always prioritise the BTU/hr rating for accuracy. HP is a less precise measure of cooling capacity.

Your calculation gives you a minimum cooling requirement. Look for a chiller model that exceeds this number. Do not pick a model that exactly matches your calculation. Selecting a chiller with slightly more capacity provides a buffer. It ensures the unit does not have to run at 100% capacity all the time. This improves its lifespan and efficiency.

For applications like cold plunge tubs, the primary goal is the initial temperature pulldown. The calculation is different. Here, you need to calculate the energy required to lower the entire water volume to your target temperature within a specific time.

Formula for cold plunge pulldown:

Required BTU/hr = Required Watts x 3.41

Example for a cold plunge:

You want to cool a 600 Litre tub from 25°C to 10°C (ΔT = 15°C) in 5 hours (18,000 seconds).

Required Watts = 37,674,000 / 18,000

Required Watts = 2093 W

Required BTU/hr = 7137 BTU/hr

For this cold plunge, you need a chiller with over 7100 BTU/hr capacity to meet your pulldown goal.

Sizing Examples for Different Systems

Applying these calculations to specific scenarios makes them easier to understand. Here are three detailed examples.

Example 1: DWC Hydroponic System

A grower uses a deep water culture (DWC) system in a grow tent.

System Volume: Four 50L reservoirs, connected. Total Volume = 200 Litres.

Equipment:

- One 40W water circulation pump.

- One 60W air pump for air stones.

- One 450W LED light above the system.

Temperatures:

- Ambient water temperature in the tent is 27°C.

- Target nutrient temperature is 20°C.

Calculation:

- Total Wattage: 40W + 60W + 450W = 550 Watts.

- Base Heat Load: 550 W x 3.41 BTU/hr = 1875.5 BTU/hr.

- Safety Buffer: The grow tent gets warm. A 25% buffer is appropriate.

- Final Required Size: 1875.5 BTU/hr x 1.25 = 2344 BTU/hr.

Conclusion: The grower should select a water chiller with a cooling capacity of 2400 BTU/hr or more. This ensures the unit can handle the total heat load and maintain a stable 20°C.

Example 2: Saltwater Reef Aquarium

An aquarist has a saltwater aquarium in their living room.

System Volume: 350L display tank plus a 100L sump. Total Volume = 450 Litres.

Equipment:

- One 80W return pump in the sump.

- Two 30W wave makers in the tank.

- Two 160W LED light fixtures.

Temperatures:

- The living room is air-conditioned, but the tank temperature reaches 28°C.

- The target tank temperature is 25°C.

Calculation:

- Total Wattage: 80W + (2 x 30W) + (2 x 160W) = 80 + 60 + 320 = 460 Watts.

- Base Heat Load: 460 W x 3.41 BTU/hr = 1568.6 BTU/hr.

- Safety Buffer: The room is climate-controlled. A 15% buffer is sufficient.

- Final Required Size: 1568.6 BTU/hr x 1.15 = 1804 BTU/hr.

Conclusion: The aquarist needs a chiller rated for at least 1800 BTU/hr. This size will maintain the crucial 25°C required for delicate corals and fish.

Example 3: Home Cold Plunge Bath

A person sets up a cold plunge tub on their covered patio.

System Volume: A 700L tub.

Equipment:

- One 75W pump for filtration and circulation. The heat load from this is minor compared to the pulldown requirement. The main calculation is for pull-down time.

Temperatures and Time:

- The starting water temperature is 28°C on a warm day.

- Target plunge temperature is 8°C. (ΔT = 20°C).

- Desired pulldown time is 6 hours (21,600 seconds).

Calculation:

- Required Watts: (700L x 4186 x 20°C) / 21,600 seconds.

- Required Watts: 58,604,000 / 21,600 = 2713 Watts.

- Required BTU/hr: 2713 W x 3.41 = 9251 BTU/hr.

- Safety Buffer: Add a 10% buffer for ambient heat gain through the tub walls. 9251 x 1.10 = 10,176 BTU/hr.

Conclusion: A chiller with a capacity of 10,000 BTU/hr or higher is needed. A smaller unit would take much longer to cool the water, making it less practical for daily use.

Quick Sizing Reference Table

Calculations provide the most accurate sizing. This table offers general estimates for common setups. Use it as a starting point. Your specific heat load from equipment and ambient conditions will change the final requirement.

| Application | Water Volume | Common Heat Load Sources | Recommended Chiller Size |

|---|---|---|---|

| Small Hydro System | 50 - 100 L | 250W Light, Small Pumps | 1000 - 1300 BTU/hr |

| Medium Hydro System | 100 - 250 L | 600W Light, Pumps | 1,500-3,000 BTU/hr |

| Large Hydro System | 250 - 500 L | 1000W+ Lights, Pumps | 3,000-6,000 BTU/hr |

| Nano Aquarium | 30 - 80 L | Small Pump, LED Light | 1,200-2,000 BTU/hr |

| Medium Aquarium | 80 - 250 L | Pump, Heaters, Lights | 2,000-4,500 BTU/hr |

| Large Aquarium | 250 - 600 L | Large Pumps, Lights | 7,000-15,000 BTU/hr |

| Small Cold Plunge | 300 - 500 L | Fast Pulldown Required | 5000 - 7500 BTU/hr |

| Large Cold Plunge | 500 - 800 L | Fast Pulldown Required | 7500 - 12000 BTU/hr |

Final Factors in Your Decision

Your calculations give you the required cooling capacity. Consider these final factors before you make a purchase.

Chiller Placement and Ventilation

Water chillers generate heat as they cool your water. They vent this heat into the surrounding air. Placing a chiller in a small, unventilated closet reduces its efficiency. The unit will heat up the closet air, which then makes the chiller work harder. Always install your chiller in a location with good airflow. Leave several inches of clear space around all ventilation grilles.

Plumbing and Flow Rate

The distance and complexity of your plumbing affect performance. Longer pipe runs, sharp elbows, and vertical climbs all increase head pressure. This reduces the actual flow rate from your pump. Ensure your pump is strong enough to deliver the chiller's required flow rate after accounting for these plumbing losses. A dedicated pump for the chiller is often the best solution.

Insulation

Insulating your system reduces the passive heat load from the environment. Insulate your hydroponic reservoir, aquarium sump, or cold plunge tub. Use foam board or other insulating materials. This reduces how often your chiller needs to run. It saves electricity and can sometimes allow you to use a slightly smaller chiller.

At Hydro Experts, we are veterans in helping you choose the right water chiller size for your system. Go to our website now to see our industry standard offerings.

FAQs

No. An undersized chiller will struggle to reach your target temperature. It will run constantly, leading to high energy consumption and premature failure of the unit. Always choose a chiller that meets or exceeds your calculated requirement.

Not necessarily. A significantly oversized chiller will cool water too quickly, causing the unit to short-cycle (rapid on/off cycles). This is inefficient and puts extra wear on the compressor, reducing its lifespan. A slightly oversized chiller is fine — a massively oversized one is not.

The ambient room temperature has a major impact. A system in a 30°C room requires a much larger chiller than the same setup in a 20°C room. Heat from the room constantly enters the water, so always include a safety buffer in your heat load calculation.

HP (Horsepower) measures the compressor's motor power, while BTU/hr measures how much heat the unit can actually remove. Two chillers with the same HP can have different BTU/hr ratings depending on design and efficiency. Always use the BTU/hr rating as your main selection factor.

Most water chillers do not include a built-in pump. They require an external pump that delivers the correct flow rate (L/h) as specified by the manufacturer. You may use an existing system pump, but it must match the chiller's required flow for optimal performance.